What is Dangerous Goods and How Does it Work, You Need to Know About Shipping Hazardous Materials:

Hazardous Materials, “a material (such as flammable or poisonous material) that would be a danger to life or to the environment if released without precautions”. According to the Federal Motor Carrier Safety Administration (FMCSA), HAZMAT include categories of materials such as explosives, gases, flammable liquids or solids, poisonous or infectious substances, radioactive material, corrosives and more. Because of the dangers of these materials, there are regulations specifying how they must be transported. These laws exist to protect the general population as well as those involved in preparing and moving hazardous materials. Here we’ll provide you with a general overview of some important rules for the ground transportation.

Shipper Responsibilities:

When it comes to shipping hazardous materials there are certain actions the shipper is responsible for completing. The major ones include: Determining that a shipment is HAZMAT, proper shipping name, class/division, identification number, hazard warning label, proper packaging, correct marking, employee training, shipping papers (aka, BOL), emergency response information & telephone number, certification, compatibility, blocking & bracing, placarding, security planning, and incident reporting.

Carrier Responsibilities:

Carrier and shipper responsibilities often overlap. When a carrier performs a shipper requirement, the carrier must complete that function in accordance with the regulations. Carriers are responsible for ensuring that the cargo space of the vehicle is suitable for the material being shipped. The truck must be in good mechanical condition. They must also make sure that the shipper has properly described and packaged the materials to be transported.

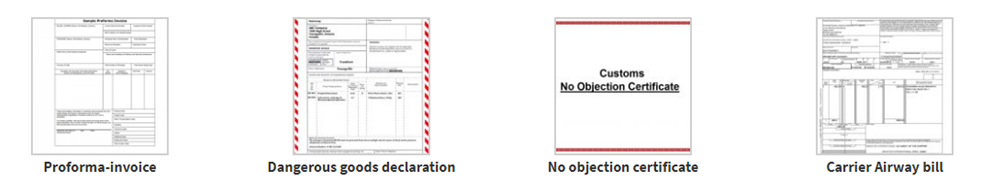

Shipping Papers:

Shipping papers, as defined in the HAZMAT regulations, are any shipping documents created to communicate a hazard and includes all the required information. A bill of lading may be used as shipping papers if desired. One critical piece of information that must be on hazardous material shipping papers is an emergency response phone number that will be monitored at all times while the material is in storage and during transport. It must be a number for a person who is knowledgeable of the hazardous materials being shipped and the necessary emergency response procedures. If not a direct contact number for such a person, it should be for someone who has immediate access to an appropriate party.

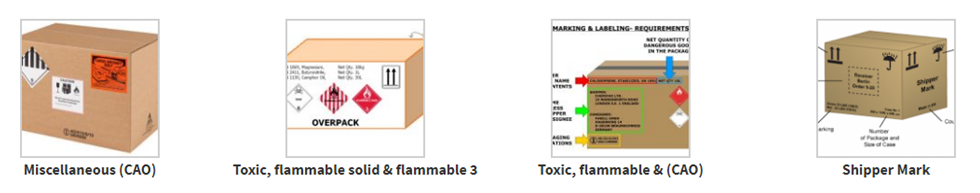

Marking:

When marking hazardous materials, a minimum requirement is the proper shipping name and identification number of the materials being shipped. Markings must be in English, durable and not blocked from view by other markings or labels. Additional markings may be required, depending on the materials being transported.

Labeling:

Labeling of HAZMAT must comply with regulations as well. Each shipper and carrier involved in the transportation of hazardous materials is responsible for making sure proper labeling is used.

Placarding:

Each bulk package, unit load device, freight container, rail car, or transport vehicle containing any amount of hazardous material must be placarded on each end and side according to hazardous material regulations (HMR).

Training:

Any organization involved in the handling of hazardous materials must meet communication requirements and have trained HAZMAT employees. This helps ensure regulations are properly followed and materials are handled correctly.

Security Plans:

Employers involved in the handling and transport of hazardous materials must also establish and implement a security plan according to the HMR.

Packaging:

Containers intended to carry hazardous materials during transport must pass, or be capable of passing, a series of performance tests prior to being authorized for this purpose. Packaging requirements include vapor pressure, material type and chemical compatibility related to the material to be contained. The manufacturers of such packaging must provide written notice to their customers of any shortfalls or actions taken to conform to required HMR specifications. It is the responsibility of the shipper to confirm that all packaging they use meets the necessary requirements.